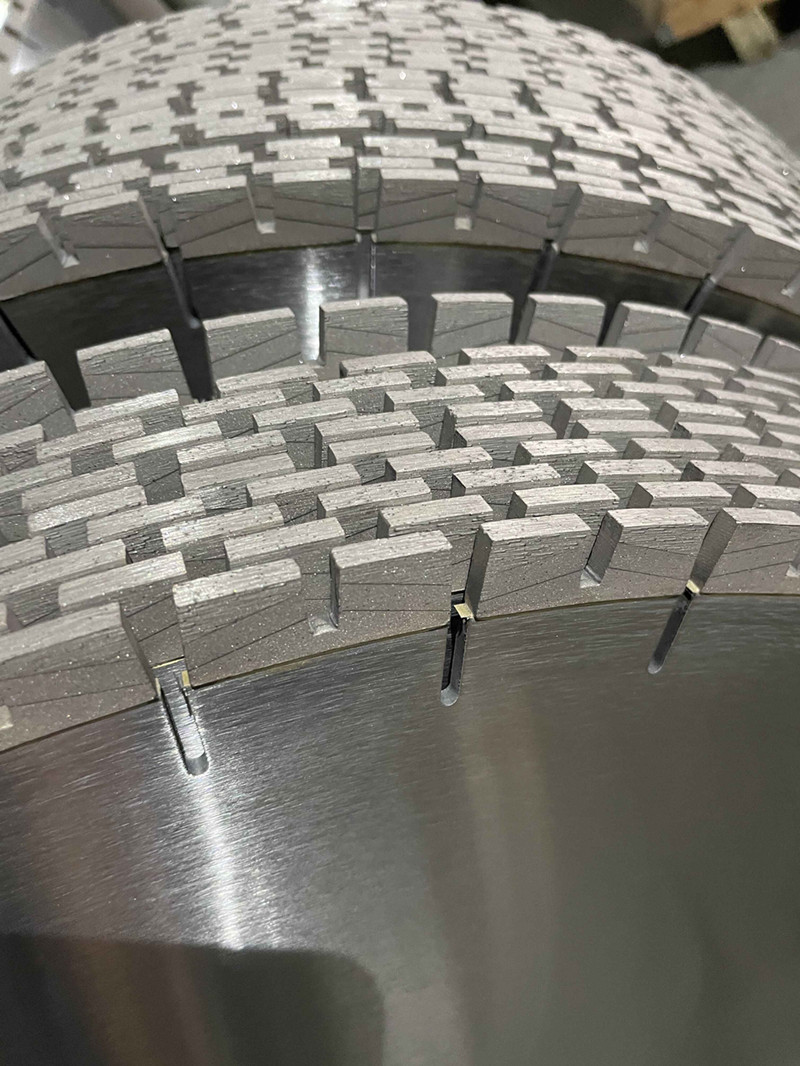

1. Lelee n'ime ime na n'èzí nke oghere ndị a na-ahụ anya, ọkpụkpụ na ọnụ ọgụgụ nke ezé nke mkpụrụ dị ka mmepụta ihe a chọrọ, ma lelee nkọwapụta, ọnụọgụ na radian nke akụkụ diamond.Mgbe ahụ na-egweri chamfer dị n'èzí nke mkpụrụ n'elu ngwa ejiji.Jiri mgba ọkụ C hichaa elu ịgbado ọkụ nke isi na akụkụ ahụ, ma tinye ihe na-ere ahịa.

2.Select kwesịrị ekwesị ịgbado ọkụ agụba dị ka saw agụba nkọwapụta na-ewu chọrọ.Obosara agụba ịgbado ọkụ na-adịkarị 0 karịa ọkpụrụkpụ isi.Ọkpụrụkpụ nke ịgbado ọkụ agụba ga-0.25-0.30mm mgbe ịgbado ọkụ saw agụba na dayameta nke 5-1 mm na ihe karịrị 1500mm;Mgbe ịgbado ọkụ ahụ agụba na dayameta na-erughị 1500mm, ọkpụrụkpụ nke ịgbado ọkụ agụba ga-0.15 ~ 0.25mm.

3.Wụnye isi, gbanwee ọnọdụ ahụ, mee ka ihe nkedo na-edozi ahụ sie ike, tinye splint jụrụ oyi, gbanwee ngwaọrụ na-atụgharị akụkụ na nkedo nkebi, gbanwee okpomọkụ ịgbado ọkụ, nchekwa ọkụ na oge oyi dị ka usoro a chọrọ, ma rụọ ọrụ. ịgbado ọkụ.

4.Mgbe ịgbado ọkụ na saw agụba na elu-ugboro ngwá, bugharia isi 180 Celsius C maka nke ọ bụla nke welded, ka weld symmetrically zere annealing ma ọ bụ mpaghara deformation mere site ekpo oke ọkụ nke isi.

5.Mgbe ịgbado ọkụ ndị òtù hụrụ agụba, weld nkebi na kpọmkwem ọnọdụ dị ka eze okirikiri nhọrọ ukwuu.

6. Mgbe ịgbado ọkụ nchara, a ga-eme nyocha onwe ya.

Oge nzipu: Mar-04-2023